So you have found yourself in the market for a new wheel(s) for your vehicle but the terminology on this and other sites is unfamiliar. When it comes to the difference between lugs and center bore you are unsure what those terms mean and if they are important. Don’t worry, we will explain the basics of what you need to know to make certain you select the right wheel for your vehicle.

Lug Nuts and Bolts

Your wheel assembly will use either lug nuts or lug bolts. Lug nuts attach the wheel to the existing threaded wheel studs. Whereas lug bolts are threaded into a hole in the wheel’s hub where no wheel stud is present.

Example:

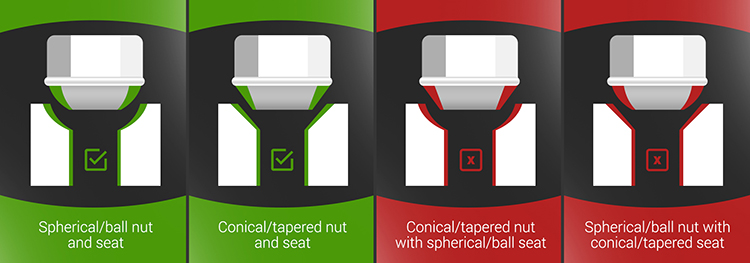

Whether you are using lug nuts or bolts, you must determine what type of “seat” your wheel has. This refers to the shape of the lug area where the wheel and nut meet. There are three main types: conical, ball or flat. Conical (or tapered) has a 60 degree angled base whereas ball seat has a rounded base and flat has a completely flat base. Lastly, don’t forget to measure the thread size, thread pitch, outside diameter and length needed.

Example of correct lug seat:

Bolt Pattern

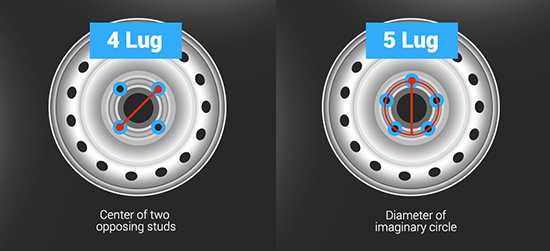

The wheel bolt pattern refers to how many lug holes there are and the diameter of a circle drawn through the center of the holes. The bolt pattern is expressed by two numbers.

(AxB)

A=the number of lug holes on the wheel

B=the diameter of the circle

It is very easy to determine the diameter of the circle for wheels with an even number of holes. Simply select two opposing lug holes and measure the distance between the centers of each hole. Determining the diameter for a 5-hole wheel can be a little trickier if you do not have a bolt pattern gauge. You must form an imaginary circle through the center of all five holes and measure the diameter of this circle. This will only be an estimate but there are many sources online to confirm your vehicles bolt pattern.

Example:

We know it’s a bit confusing so we have created a downloadable template free to use to determine your bolt pattern.

Download Bolt Pattern Template (Coming Soon)

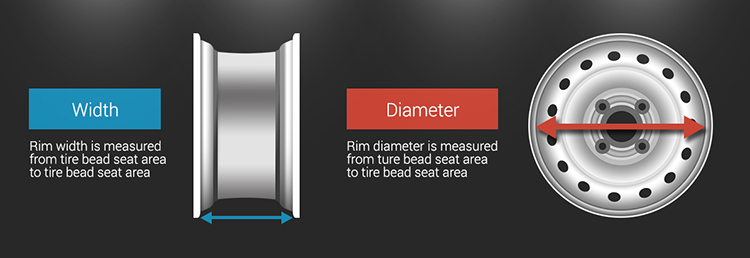

Width

Determining the wheel width is relatively easy once the tire has been removed. The width will be measured in inches in ½ inch increments and be between 5” and 8”. On the wheel there will be a series of numbers stamped with two numbers represented as AxB (this can also be displayed as BxA). The smaller of these two numbers, or B, will be the width of the wheel. If those markings are unavailable, you can also measure the wheel itself. Simply measure the distance from the inside of both flanges (this is where the tire sits).

Diameter

The diameter of your wheel is also relatively easy to determine once the wheel has been removed. As discussed above from determining width, there will be a series of numbers stamped. The diameter is represented by that first number, or A. You can also physically measure the wheel if those numbers are unavailable. Make sure to measure across the face of the tire, being sure not to include the wheel lips also called flange.

Example:

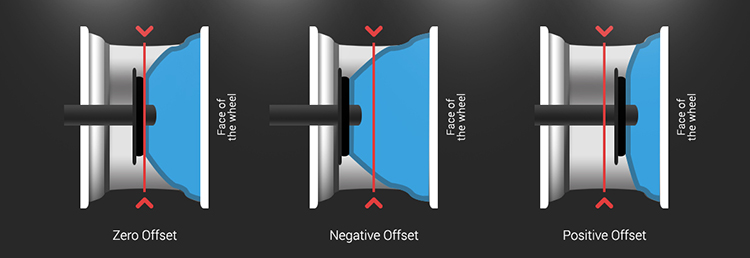

Offset

The offset of the wheel refers to the placement of the centerline of the wheel in relation to the wheel hub on the vehicle. This is measured in millimeters and is either positive, negative or zero, meaning it is even with the hub. If you are going to change the width of your wheels, you will need to pay attention to this offset as improperly offset wheels will impact the handling.

Example:

Center Bore

Finally, let’s take a look at center bore. The center bore is the rounded opening on the back of the wheel that will fit into the vehicle hub. The wheel can come from the factory with the bore fit to a specific model or it may have a series of rings in order to allow the wheel to be fitted to multiple vehicles. These are usually measured in millimeters and must be an exact fit.

Example:

Now that you have a basic understanding of wheel specifications, you should be able to understand the terminology used on this site. Remember, if you have any questions, don’t hesitate to contact us with any questions.